Manufacturing's Invisible Productivity Trap

A strategic brief for CEOs and the leadership teams who must respond

The quiet problem no one wants to admit...

Across nearly every industrial sector, productivity growth has stalled. Not because leaders lack ambition. Not because teams lack capability.

But because the underlying system—the operating model—was architected for a world that no longer exists.

The research is unequivocal:

Manufacturers are not being out-worked. They are being out-architected.

Two forces are colliding:

- The accumulated advantage of past decisions (structures, tooling, systems, governance)

- The triggers and mitigants that shape how work actually gets done today

When these drift out of alignment, systems slow down—even as expectations rise.

This is the hidden productivity trap.

Why this matters to you, CEO...

If you're reading this, you're probably already sensing it: the same investment dollars are producing less gain than they used to.

Digital programs run... but the organizationnever becomes materially faster.

Your plants feel it.

Your frontline feels it.

Your COO feels it most.

Two Distinct Productivity Patterns

Every manufacturer today falls into one of two system archetypes,

each with its own causal structure:

Growth-oriented (but stalled)

Ambitious roadmaps, innovative teams, and increasing complexity — but slowed down by decision latency, legacy governance, and uneven digital adoption.

The causal model here exposes how growth hides friction until it becomes structural.

Cost-containment (over-optimized)

Disciplined, reliable, efficient — but unable to create new bandwidth, adapt fast enough, or capture advantage from next-generation technology.

The causal model shows how cost control eventually becomes a drag on competitiveness.

Your organization fits into one of these patterns.

Your COO needs to know which — and how to shift it.

Understanding the System Architecture

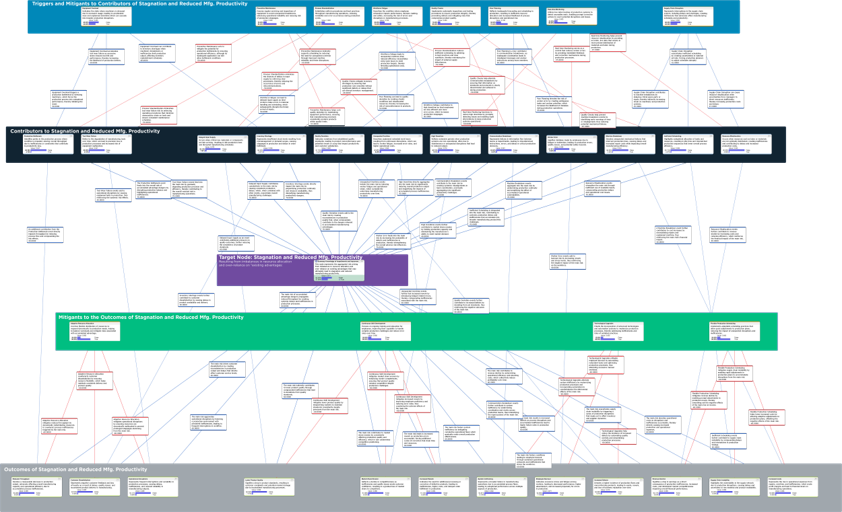

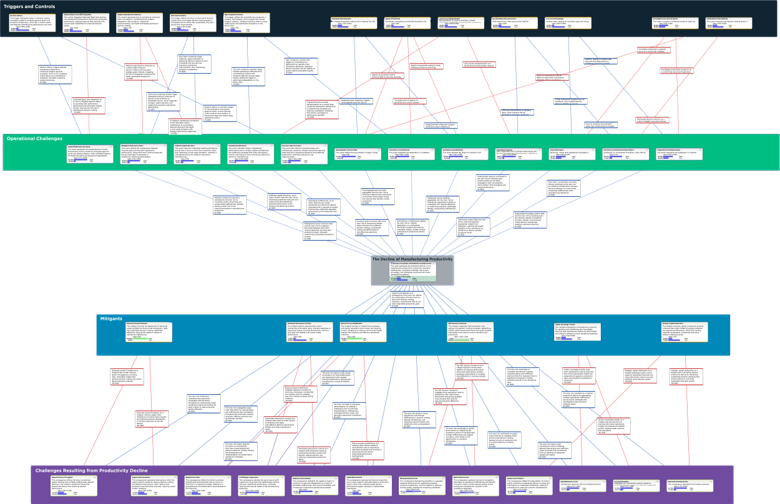

These causal models reveal the hidden relationships between accumulated advantages, triggers, and mitigants that shape manufacturing productivity.

Accumulated Advantage Model

How past decisions in structures, tooling, systems, and governance create compounding advantages—or constraints—in your operating model.

Triggers & Catalysts Model

The catalysts that either accelerate productivity or expose structural weaknesses—and how your organization responds to them.

These models form the foundation of the COO Diagnostic—revealing where your system architecture is helping you and where it's holding you back.

A 10-Question COO Diagnostic

Give this to your COO. Ask them to run it.

Growth vs. Cost-containment System Classification

Stress points across decision velocity, architecture, governance, and workforce utilization

The 3-5 highest-leverage priorities for the next 12 months

System-level risks that accumulate slowly…but suddenly matter

A recommended conversation path for your leadership team

If you want your team to move faster...

Expose them to faster ideas

Mike Carroll's One Degree Dispatch

Weekly insights from one of the most forward-thinking COOs of the last decade. Agentic operations, causal AI, operating-model rewiring, and the organizational trust layer behind all of it.

→ Read One Degree Dispatch

COO Perspectives Newsletter

A short, practical brief specifically designed for COOs and EVPs of operations; a quick read in minutes,but will help you alter the next 90 days of decisions.

→ Subscribe to COO Perspectives

Why CEOs share this page with their leadership teams

Because this isn't another digital transformation pitch.

It's a structural view of why productivity has stalled — and a roadmap for how the best organizations are pulling ahead.

And because the CEO can decree ambition…

but only the COO can re-architect the system to deliver it.